|

| **Editor's Note: If you cannot see the images in this newsletter, click within your e-mail system to view/load graphics or change your settings to allow graphics to be viewed in recieved e-mails. |

| View this newsletter as a webpage

View this newsletter as a pdf file

What's New Links to Articles of Interest A Letter from Lewis Achieving Higher Yields Montag Goes to Africa Nutrient Calculator Product Feature 8 Things Really Efficient People Do |

|

|

Montag Announces New Brochure Now Available Check out our new brochure! Montag Presents at Pro-Farmer Event Montag had the opportunity to speak about nutrient placement at the recent Pro Farmer meetings in Lincoln, NE and Mankato, MN. And we were very pleased with the interest shown in our message and our products.

If you would like information on complimentary tickets to the upcoming Pro Farmers events in either Peoria or Des Moines, simply send us a e-mail at info@montagmfg.com and we will be happy to get back to you with additional information. These tickets are available on a first come first serve basis. |

|

| Several years ago Montag started developing a video library as a way to tell our story as well as demonstrate the features and benefits of the quality products we produce. Our feature video for this issue is one that tells the Montag story.

Also, you can connect to the complete Montag video library by clicking here. |

|

|

Search Agtalk Forums to see who's talking about Montag! Strip Till Benefits Growers with experience using strip-till with a fertilizer program Micro-Nutrients |

|

| Click Here for Montag Hose Routing Information |

|

Iowa Power Show. January 28th-30th. Des Moines, Iowa.

World Ag Expo. February 11-13th. Tulare, California.

Peoria Pro Farmer Profit Briefing. February 17th-18th. Peoria, Illinois.

MN Conservation Tillage. February 18th-19th. St. Cloud, Minnesota. Click here for a flyer about the event.

Des Moines Pro Farmer Profit Briefing. July 15th-16th. Des Moines, IA. |

Montag has been at two farm shows since our last newsletter and also attended a profit briefing seminar with the Pro-Farmer publication. I continue to hear from growers and producers an interest in banding fertilizer. I would say the majority of interest is in banding the fertilizer 4 to 7 inches in depth. Right now to get more than 5 inches a shank or knife must be used.

Much of the Corn Belt this past season had nitrogen deficient corn. Where did the nitrogen go? Most of it was washed away into water- ways and ultimately into the Mississippi river. Bill Northey the Iowa Secretary of Agriculture has stated that the agriculture community should fix the problem before the Federal Government gets involved with regulations. Mr. Northey is the co-chair of the hypoxia task force that includes 12 states. Basically the goal of the task force is to reduce the amount of Phosphorus and Nitrogen applied for fertilizer therefore reducing the run off of each nutrient. Their goal is to educate growers in new technology (variable rate, application tools, etc.) to help reduce runoff voluntarily. Much of the Corn Belt this past season had nitrogen deficient corn. Where did the nitrogen go? Most of it was washed away into water- ways and ultimately into the Mississippi river. Bill Northey the Iowa Secretary of Agriculture has stated that the agriculture community should fix the problem before the Federal Government gets involved with regulations. Mr. Northey is the co-chair of the hypoxia task force that includes 12 states. Basically the goal of the task force is to reduce the amount of Phosphorus and Nitrogen applied for fertilizer therefore reducing the run off of each nutrient. Their goal is to educate growers in new technology (variable rate, application tools, etc.) to help reduce runoff voluntarily.

This past growing season much of Midwest had a difficult time planting. Delays in planting and abundant rainfall lead to nitrogen deficient corn. Much of this issue was from fall applied anhydrous ammonia from the information I have received from several growers. I want to inform growers that there is a granular alternative to a fall applied anhydrous ammonia (N) - encapsulated urea also known as ESN (environmentally smart nitrogen). Basically it is urea with a polymer coating. More coats, the longer it takes to break down. Many use it to stagger the total N for the entire growing season. At Montag we like it because the coating prevents urea from absorbing moisture. When urea absorbs moisture it becomes sticky and tends to clump up and does not flow very well. Urea has a critical relative humidity of 72%. Most growers in the upper Midwest do not have problems with urea unless they forget to close the lid on the tank when it rains. Another issue we see is combining urea with ammonium sulfate which lowers the critical relative humidity to 56%. Usually a caked up auger is running this combination. You can find more information on ESN at this web site, www.smartnitrogen.com. Visit Montag at the Iowa Power Farm show in January and the World Ag show in February. Lewis Brazil Territory and Sales Manager Montag Manufacturing Know someone who would love our Newsletter? Use the Send to a Friend Feature or e-mail us at info@montagmfg.com  |

||

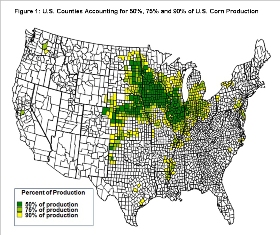

Strategies for matching crop nutrient uptake requirements with fertilizer and placement technologies

Dr. Fred Below Dr. Fred Below

Professor of Plant Physiology University of Illinois Background Adequate crop nutrition is an often over-looked prerequisite of high yield corn and soybean production. Although we should strive for greater fertilizer use efficiency (yield per unit of input), it is clear that continued increases in yields will require more total nutrients, not less. For example, our research has shown that a 230 bushel/acre corn crop will take up about 100 lb P2O5/acre, and nearly 80% of this will be removed with the grain. This implies that at least 80 lb P2O5/acre needs to be supplied by a phosphorus fertilizer just to compensate for that removed by the grain. Besides phosphorus, nitrogen, sulfur, and zinc also have large (>50% of total plant uptake) grain requirements. As such, these four nutrients (N, P, S, and Zn) are particularly important and should be supplied in adequate amounts for high yield corn production. An additional challenge, however, is that some nutrients such as P and Zn are immobile in the soil. Therefore, placement should be considered in addition to rate. To read the complete study click here. |

||

| Report from Werner Nel with JWL

JWL Agricultural Suppliers from Ermelo in the Mpumalanga province of South Africa has been appointed as the importer and distributor of Montag products in South Africa. Over the last few years labor problems have forced commercial farmers to mechanize and bigger equipment is bought to do work more effectively and with less labor. Although locally manufactured products for distributing bulk fertilizer are available, JWL recognized the uniqueness of the Montag system in its metering system providing very accurate inter-row placement of fertilizer, a problem experienced with local equipment. Then there is the build quality of Montag being far superior to the competition.

Three 6 ton bins mounted on Montags steerable carts were put to the test during the 2013 planting season, which was October to November. Two machines were running behind 12 row 36 inch stack fold planters and one was attached to a 12 row 30 inch strip-till rig. The results were very satisfactory. Some of the growers indicated that this was the best piece of equipment they bought in a very long time. The accuracy and build quality impressed growers. With a very short planting window in some parts of the country, one cannot afford to have equipment not being able to deliver and causing the planting process to be slowed down or even coming to a stop. Montag proved to be just that! |

||

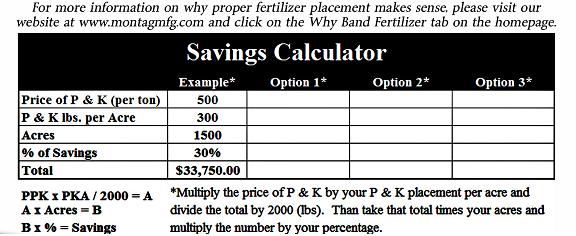

Take a few minutes and see how proper fertilizer placement can have a positive effect on your bottom line.

Click here to access more information about how Montag can help you! |

||

| Montag Screens

Montag screens are designed and manufactured to accomplish two goals for the producer:

|

||

| An Article from Inc.

By Kevin Daum Most everyone would like to be more efficient. Just think, you would spend less time doing the things that you don't enjoy and more on the things that bring satisfaction, happiness and profit. Some people are actually very adept at efficiency. They manage every manageable moment so they have more time for themselves to do the things they love. Here are eight techniques efficient people use to gain that freedom. Click here to read the full article from Inc. Magazine. |

||

Click here for access to all of our Montag Brochures

Click Here for access to technical information on Montag Products Click here to view one of our current ads in Fastline Contact us with questions or for more information 3816 461St. Ave. Emmetsburg, IA 50536 Phone: 712.852.4572 E-Mail: info@montagmfg.com Website: www.montagmfg.com |

|

|